Our new twin pallet high performance Brother R650X2 is more than a match for the needs of our growing customers by increasing productivity on many product lines, significantly boosting output and impressively reducing lead times.

Month: December 2022

Putting greater power behind punch cell

We are delighted to announce greater investment with the newest member to the Broxton operation – World-Class punch cell production technology. The newly released TruPunch 3000 delivers.

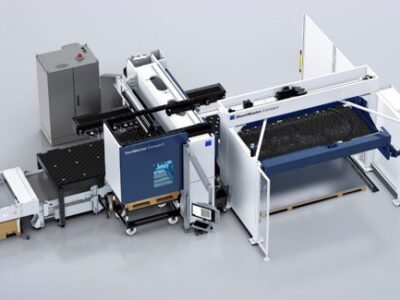

New fibre laser with automation

To ensure we meet the demands of our long standing customers growth Broxton have invested in a Trumpf Trulaser 1030 4KW fiber laser with LiftMaster Compact sheet load and unload automation.

A bigger & better new screen print facility

Screen printing and screen generation in-house is a vital service for us and for our customers. This final process requires a high level of skill and accuracy to achieve consistent results in line with our ‘Make it Perfect’ mantra. In 2019, when we built a dedicated powder coating building as Site 2, the screen-printing room remained at Site 1 which was not ideal logistics. We have now built a new clean room that is twice the size and has a dedicated dark room for screen production.

Our new software to improve your hardware

Alongside our recent investment in 24/7 automated 5-axis milling we have made another significant investment in CAM software in a switch from Hexegon Manufacturing’s Edgecam software to HyperMILL by Openminds Software.

Doubling our milling capacity

In the last three years we have experienced sustained growth in higher volume aluminium milled parts leading to an investment that supports our strategy of working on a single shift whilst investing in automation and lights-out production capacity.