Our commitment to precision

Behind every component we manufacture is a team of individuals whose skills, curiosity and dedication keep our standards high and our future bright.

Behind every component we manufacture is a team of individuals whose skills, curiosity and dedication keep our standards high and our future bright.

It starts with culture.At Broxton, process excellence isn’t just about systems and checklists. It’s also about a mindset that’s in the business. One that’s shared by every team member and from first cut to final inspection.

We’ve been making some behind-the-scenes changes at Broxton to help production flow more smoothly across the shop floor.

When deadlines tighten and markets shift, supply chain resilience becomes the new competitive advantage.

Whenever OEM’s come to us, we always provide a consultative approach. It’s always been that way for good reason.

Managing a project across different suppliers for CNC, sheet metal, finishing and assembly?

One of the best things about manufacturing is knowing when to follow the spec and when to go further.

We’ve been manufacturing parts for one of our audio clients using their specified paint as requested.

Sometimes you need to challenge the brief to deliver the best result for your customers.

Our commitment to zero-defect output starts long before a part hits the production line.

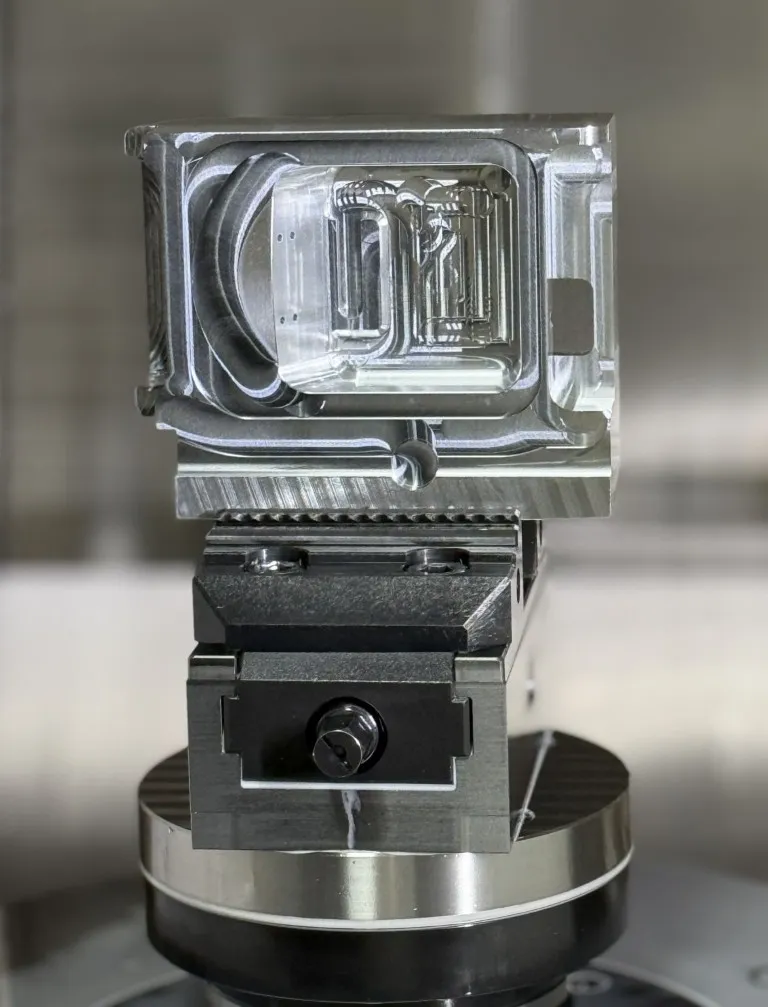

One client needed a complex aluminium part that used to take multiple setups but now, it’s one and then it’s complete.