At Broxton, our Design for Manufacture and Engineering services are driven by a team of talented engineers with a wealth of technical expertise. With significant experience across many demanding sectors, we are experts in machining aluminium and crafting sheet metal enclosures.

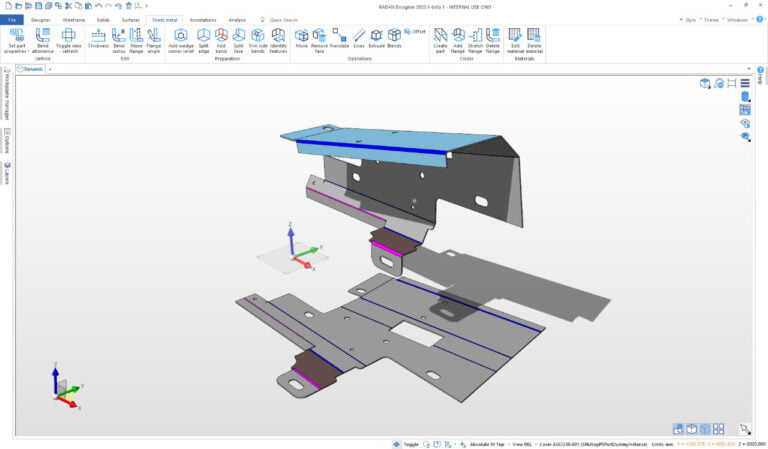

Utilizing the Solidworks CAD system and Hypermill and Radan CAM systems, we provide world-class cutting technology that optimizes the use of our high-performance machine tools. Our extensive process knowledge enhances production methods for individual parts, significantly improving production efficiency and reducing costs, while also shortening lead times.

Customers can rely on Broxton’s technical input to enhance product quality and cost-effectiveness, ensuring superior results for every project.

Helping you bring new products to market

Involving Broxton at NPI stage means we can review projects at conception of design, guiding your engineers with Design For Manufacture solutions, preventing the frustration of re-engineering at latter stages of design, resulting in reduced time to market.

Design service based on reverse engineering or from a design brief.

Engineer assigned to follow your project through every stage of manufacture to ensure most efficient method of manufacture is adopted to further drive down costs and lead times.

Reducing cost and improving quality

Advice on the use of Broxton’s comprehensive library of tooling at outset preventing the need for expensive, long lead time, be-spoke tools.

Offer advice on best materials and finishes and readily available hardware.

Helping you shorten time to market

Prototypes can be manufactured direct from 3D models whereby Broxton produce the necessary drawings required for manufacture of prototypes, further reducing Time to Market.

Helping you understand the cost of parts

Detailed costings are made for all enquiries, which reliably and accurately estimate materials, processes and costs. This enables consistent and demonstrable pricing and underpins the evolution through NPI and into production.

Collaborating more with on-line meetings

Whilst site visits are encouraged, our engineers can utilise online meeting platforms preventing the need for lengthy site visits

Time spent understanding needs and exploring solutions, pays dividends throughout the life of a product.